News

Do I need a larger slurry pump to increase the flow?

One of the common questions we get from slurry pump users is if they need a larger pump to increase the flow from their slurry pump. Typically, this happens when a pump has been performing a duty and now there is a need to increase the throughput. This is normally when a plant has reached capacity and is being debottlenecked or parts of the plant are being upgraded.

The logic of a larger pump seems to make sense. A larger slurry pump should surely produce more flow. Shouldn’t it?

As with many questions about slurry pumps, the answer really depends on the system and not just the pump. There are two basic scenarios; pump more down the same pipe or pumping through a different pipe.

Pumping through the same pipe

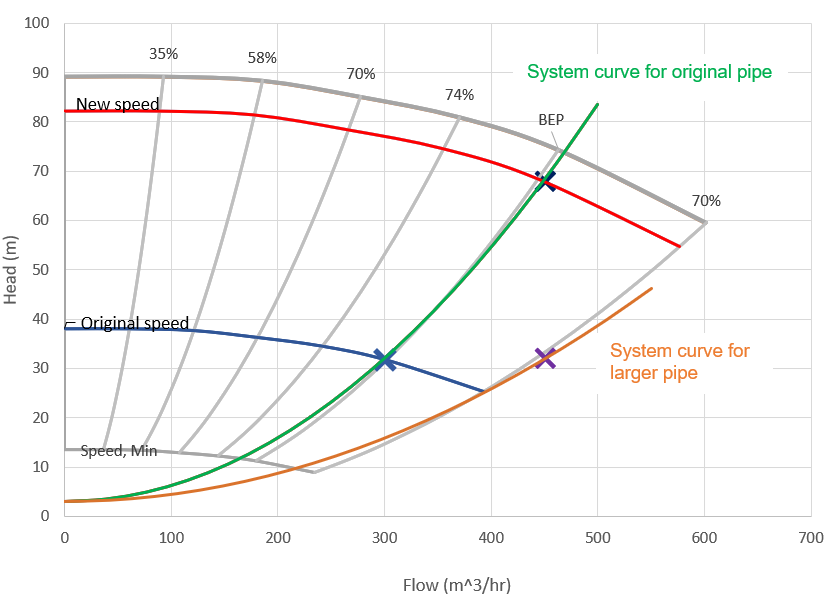

If nothing else is changing except the desired flowrate, the calculations are fairly simple. A pipe system will have a system curve and that curve, combined with the slurry pump’s performance curves will determine the duty (the green curve). System curves are parabolic due to the relationship between velocity and friction. As slurry pump duty points are varied by changing the speed, the duty points are (roughly) parabolic as well. This means increasing the flow through the pipe will increase the head at approximately the same rate as changing the speed of the pump. If the pump was operating near BEP (best efficiency point), it will continue to be close to BEP as the speed increases.

What all that means is that, if you want to increase the flow through your existing pipe, you can do it by increasing the speed of the pump (red curve).

Things to look at after that would be motor power, tip speed, particle velocity, pipe pressure rating and NPSHa.

Pumping through a larger pipe

Sometimes, running at higher pressure is not an option due to pressure restrictions, motor size, etc. If the slurry will be pumped through a larger pipe, the system curve will change to a “flatter” curve (brown curve), although still parabolic. If a larger pipe is being used, the new duty point (purple marker) would have a lower head than using the old pipe and may even be lower than the original duty head. As this will push the duty to the right on the curve, and assuming the slurry pump was operating close to BEP, it will probably push it past BEP and maybe off the curve. In this case, a larger pump is the best option as it will be running more efficiently and with lower wear.

Things to look at after that would be motor power and settling velocity.

(Typical Pump Performance Curve with system curves showing two options to increase flow from 300 to 450 m3/hr)

There are many more details that come into play, so contact KETO Pump Technology Services for the solution to your pump problem.